28

2020

-

09

Progress and Development of Desulfurization and Denitrification Engineering

With the rapid development of China's economy, emissions are also increasing. The emissions released by coal burning are huge, and the acid rain caused by it accounts for 82% of the total acid rain. According to relevant research, China's annual economc loss caused by emissions is about hundreds of millions of yuan, and the economic loss caused by acid rain pollution is about 500 billion yuan. What is the role of technology in industriy? The following is a detailed analysis.

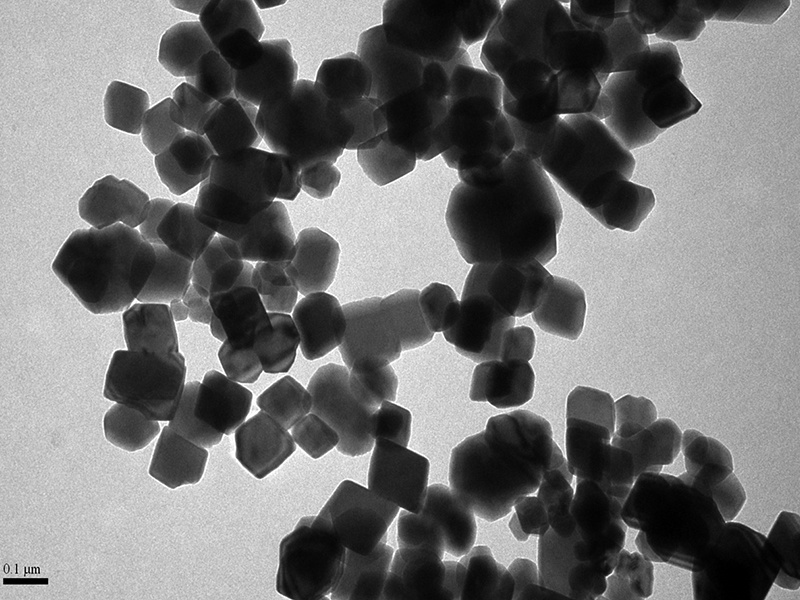

At present,desulfurization and denitration engineering technology mainly combines wet flue gas desulfurization with selective catalytic reduction or selective non-catalytic reduction denitration. The calcium method using lime or limestone is usually used for wet flue gas desulfurization, and the desulfurization efficiency is greater than 90%. The disadvantage is that the project scale is large, the initial investment and operating costs are high, and it is easy to form secondary pollution. When the selective catalytic reduction denitration reaction temperature is 250-450 ℃, the denitration rate can reach 70%-90%. The technology is mature and reliable, and has been widely used in the world, especially in developed countries. However, the treatment equipment requires a large investment, requires preheating of the flue gas, the catalyst is expensive and has a short service life, and there are problems such as ammonia leakage and equipment corrosion. The temperature range of selective non-catalytic reduction is 870~1200 ℃, and the denitration rate is less than 50%. The disadvantage is that the investment in process equipment is large, the flue gas needs to be preheated, and the equipment is easily corroded.

Over the past few decades, desulfurization and denitration engineering and desulfurization processes have been continuously developed and improved, and new process technologies have been continuously used in industrial production. Next, a brief introduction. The technology of removing sulfide from feed gas is divided into dry desulfurization and wet desulfurization. Wet desulfurization is divided into "wet oxidation method" and "amine method". Wet oxidation method is to directly convert H2S into elemental sulfur after absorbing H2S in the solution, and recover the solution after separation. In the amine process, the absorbed H2S is released by a regeneration system and sent to a Claus plant, where it is then converted to elemental sulfur, and the solution is then recycled. Wet desulfurization is mainly used to remove a large amount of sulfide in crude gas containing ammonia, coke oven gas and natural gas. Dry desulfurization uses fine desulfurization. Dry process has a high purification rate of inorganic sulfur and organic sulfur. In addition, low temperature methanol wash "NHD" is also at the same time.

Desulfurization and denitration

Next page

Next page