16

2022

-

02

What is the production process of heavy calcium carbonate?

Heavy calcium carbonate and light calcium carbonate are widely used powder filler in the plastics industry. China's annual output of plastic products has exceeded 10000 tons. According to the calculation that plastic powder filler accounts for 8% of the total plastic products and calcium carbonate accounts for 70% of the total amount of various powder fillers, China's plastic industry uses about 5.7 million tons of calcium carbonate of various specifications every year. Calcium carbonate has become an incremental material in the plastic processing industry due to its low price, easy to use, and low side effects, which has brought huge business opportunities to the calcium carbonate industry.

Production process of heavy calcium carbonate:

1. Heavy calcium state

White powder, colorless and tasteless. Stable in air. Almost insoluble in water, insoluble in alcohol. If it is dilute acetic acid and dilute nitric acid, it will bubble and dissolve. When heated to 898°C, it begins to decompose into calcium oxide and carbon dioxide.

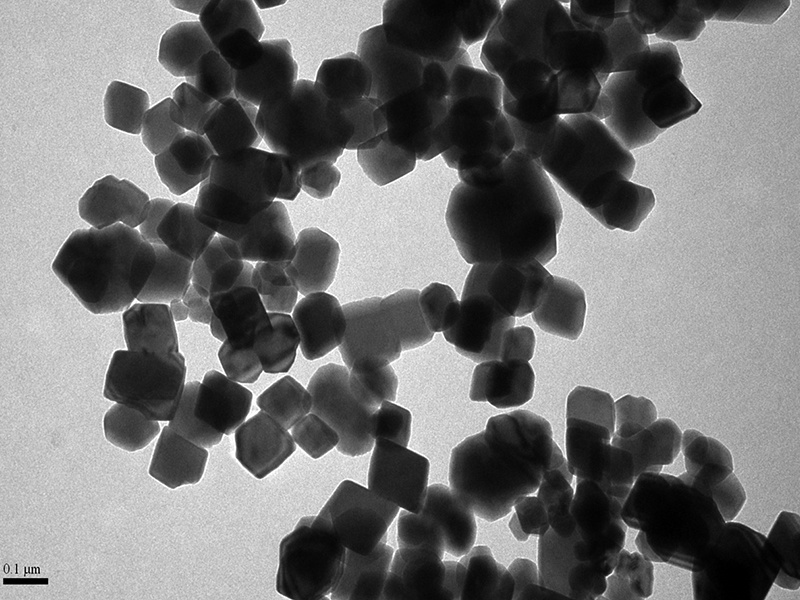

Heavy calcium carbonate has irregular shape, large particle size change, certain angular particles, rough surface, wide particle size distribution, large particle size, the average particle size is generally 1 ~ 10μm, heavy calcium carbonate according to its original average particle size (d)μm is divided into coarse grinding calcium carbonate (>3). Finely ground calcium carbonate (1~3)μm). Characteristics of ultrafine calcium carbonate (0.5~1)μm heavy calcium carbonate: a. irregular particle shape; B, wide particle size distribution; C, larger particle size.

Production method of Heavy calcium carbonate

There are two production processes:

1. Dry production process: manually select calcite, limestone, chalk, shells, etc. transported from the quarry to remove coal gangue; then, the limestone is roughly crushed by the crusher, and then ground by the Raymond (pendulum) to obtain fine limestone powder. The grinding powder is classified by a classifier. The powder that meets the particle size requirements is stored as a product package, otherwise it will be returned to the pulverizer to be pulverized again.

2. Wet production process: first put the suspension made of dry powder into the mill for further crushing, and then prepare ultrafine heavy calcium carbonate after dehydration and drying.

3. The difference between heavy calcium and light calcium

Light calcium carbonate and heavy calcium carbonate are composed of calcium carbonate, calcium carbonate is a commonly used filler in coatings, plastics and other industries. The content of grade 1 is 99.1% and that of grade 2 is 97.9%. The difference between heavy calcium carbonate and light calcium carbonate is as follows:

(1) The main difference lies in the different uses. Light calcium is used for fillers, welding rods, organic synthesis, etc., and heavy calcium is used for the production of anhydrous calcium chloride, cement, etc.

(2) It is natural calcium carbonate, which is formed by crushing calcite. Compared with light calcium carbonate, it is cheap and easy to precipitate when used in latex paint. Light calcium carbonate is also called precipitated calcium carbonate. Its particle size is less than heavy calcium carbonate, the oil absorption rate is greater than heavy calcium carbonate, and the price is higher than heavy calcium carbonate. They are used together with fillers commonly used in latex paints.

(3) Heavy calcium is made by natural crushing of ore, and light calcium is made by artificial synthesis. Widely used in coatings.

(4) Heavy calcium is stable, but relatively light calcium is easy to sink.

(5) The precipitation effect of light calcium is better, but the oil absorption is greater than that of heavy calcium, and the price is generally higher than that of heavy calcium. Although it is not as stable as heavy calcium, it still has stability. Even the exterior wall coating, its application is also very large.

Heavy calcium carbonate

Previous page

Previous page