16

2021

-

12

Application and Characteristics of Heavy Calcium Carbonate

Heavy calcium carbonate is a very important inorganic mineral, not only in industry, but also in our lives everywhere. Geologically speaking, heavy calcium carbonate is a natural mineral of the earth's crust. There are three types of ground calcium carbonate deposits: limestone, chalk and marble. According to the relevant departments of research, the world's carbonate rocks(includingHeavy calcium carbonate and dolomite) has a distribution area of 5.34 million square kilometers, accounting for 4% of the earth's land surface area. China's carbonate rock area of 3.44 million square kilometers, accounting for 64% of the world.

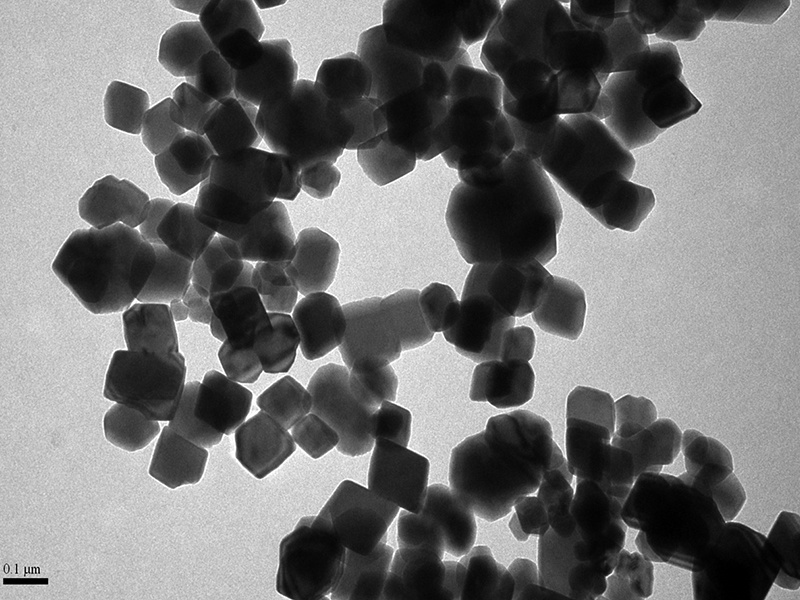

Calcium carbonate is divided into light calcium carbonate and heavy heavy calcium carbonate. Heavy calcium carbonate is characterized by color, particle size, surface characteristics, dispersion, rheology, thixotropy and crystal type can be manually controlled. Moreover, heavy calcium carbonate has high chemical purity, strong chemical inertness and good thermal stability,400 below will not decompose. in addition,Heavy calcium carbonate also has the advantages of low oil absorption rate, low hardness, small wear value, non-toxic and tasteless, and good dispersion.

Due to the above special properties, the application of heavy calcium carbonate has developed rapidly and has been widely used in industrial and agricultural fields, such as rubber, plastics, paper, paint, paint, ink, cable, medicine, fertilizer, feed, food, sugar, textile, glass, ceramics, sanitary products, sealants, adhesives, pesticides and pesticide carriers, flue gas desulfurization, water treatment and other environmental protection aspects. Use and weight of light calcium carbonate. Mainly used in paper, plastics, artificial rubber, food, food coloring, medicine, adhesives and hygiene products and other fields. In recent years, it has been reported that light heavy calcium carbonate can enhance the performance of some materials, so its application range has increased.

The use of heavy calcium carbonate in the paper industry can make the paper bright, firm in structure, easy to write, uniform coating, low friction, easy to dewet, and easy to dry. SinceIn the early 1980 s, the world paper industry successfully changed from an acidic process to an alkaline process, and the use of fillers has undergone a revolutionary change.Heavy calcium carbonate can replace wood pulp and other pigments, can improve the brightness of the paper, impermeability, porosity and bulk density. Basic processing is mainly used to produce fine printing and writing paper. For some important papers, such as newsprint, ground calcium carbonate can also be used, although it is produced in an acidic environment. At present, the amount of heavy calcium carbonate in paper coating formulations has been greatly increased, from5% ~ 10% increased to about 30%.

In the mid-1990s, the world's papermaking process reached a climax from acidic to alkaline. In terms of paper production capacity, in 1997, the alkaline or neutral papermaking process in the United States accounted for 80% of the total paper production capacity, while Western Europe accounted for 65%. By 2000, with the exception of a few specialty paper products, 95% of production capacity in the United States was already alkaline or neutral, and 80% in Europe. This transformation givesHeavy calcium carbonate has brought a huge market.

The current domestic production of paper coating grade heavy calcium carbonate can not meet the demand, so need to import to fill the gap. Application of heavy calcium carbonate in plastic polymers Heavy calcium carbonate is a very important filler, especially in Europe, accounting for the mineral filler and reinforcing agent market60% by weight.The main use of heavy calcium carbonate filler is plasticized polyvinyl chloride(cable, floor artificial leather, etc.). Among them, heavy calcium accounts for 10% ~ 30%), hard PVC (hard PVC doors and windows, profiles, plates, pipes, plates account for 5% ~ 20%, floor tiles account for 40% ~ 80%), and unsaturated polyester materials (plate molding and molding in automobile and electrical appliance industries).

Heavy calcium carbonate